USED 2001 2001 MIKRON UCP 600 5 Axis VMC

Overview

- Type

- Vertical Machining Centers (5-Axis or More)

- Manufacturer

- MIKRON

- Model

- UCP 600

- Year

- 2001

- Status

- for sale

Description

Mikron UCP 600 Universal 5-Axis Vertical Machining Centre with Heidenhain TNC 426/430 M CNC Control System, Equipped with: Step-Tec 18,000 rpm spindle; Separate spindle cooler; Unilube oil/air spindle lubrication system; Coolant tank with scraping chip conveyer; Separate coolant paper filtration equipment; Renishaw MP 12 3D IR touch probe; 3D scanning system for tool measurement TS27; 27 items of HSK-63A spindle tooling.

Specifications

| X | 20.86" |

| Y | 17.71" |

| Z | 17.71" |

| # Axis | 5 |

| Power | 21.44hp |

| RPM | 18000rpm |

| # ATC | 30 |

| Taper | HSK-63A/Din 69893 |

| Control | CNC (Heidenhain TNC426/430M) |

| Dimensions | 115.35 in x 133.85 in x 104.13 in " |

| Weight | 14330 lbs |

Mikron UCP 600 Universal 5-Axis Vertical Machining Centre

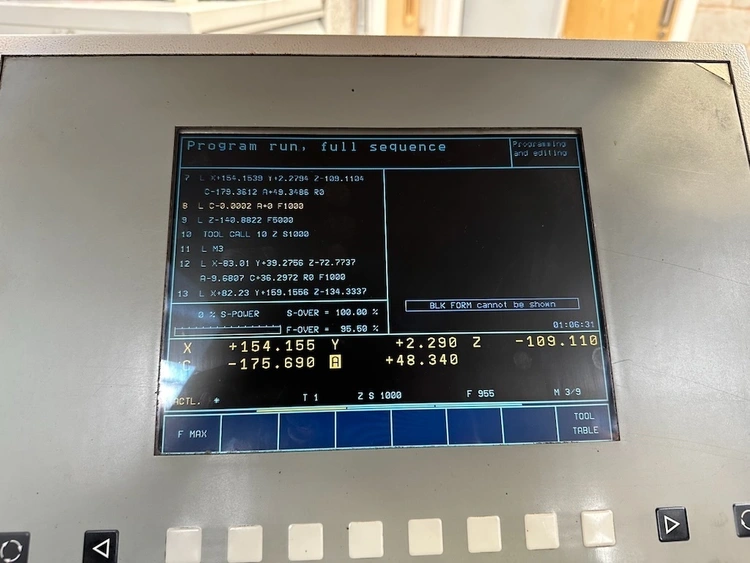

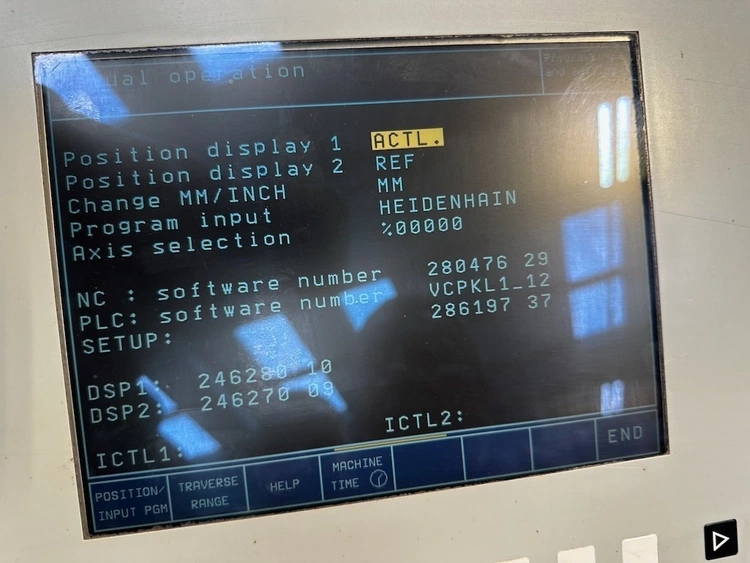

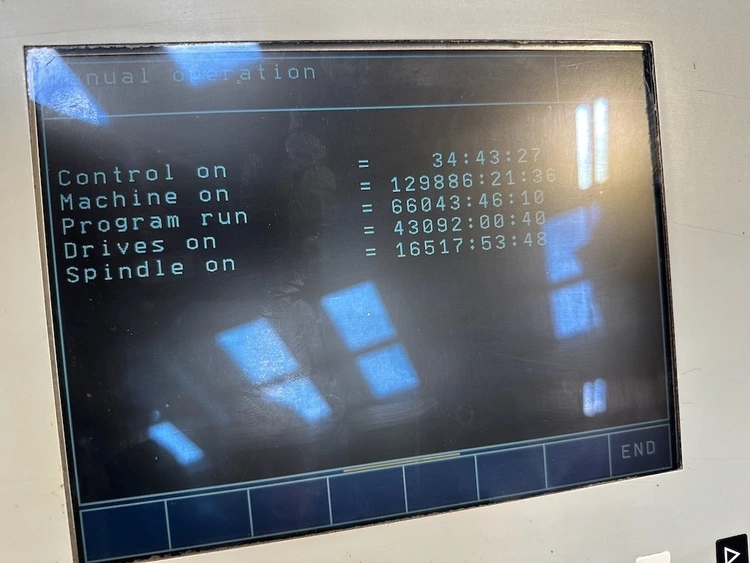

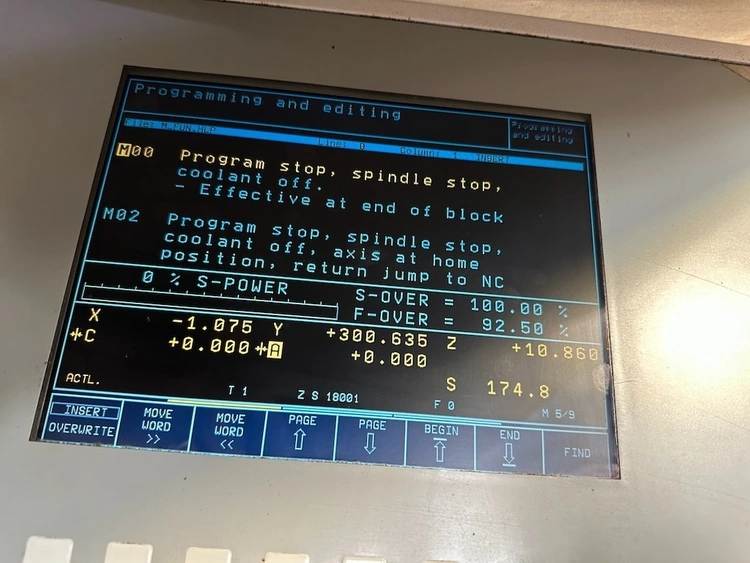

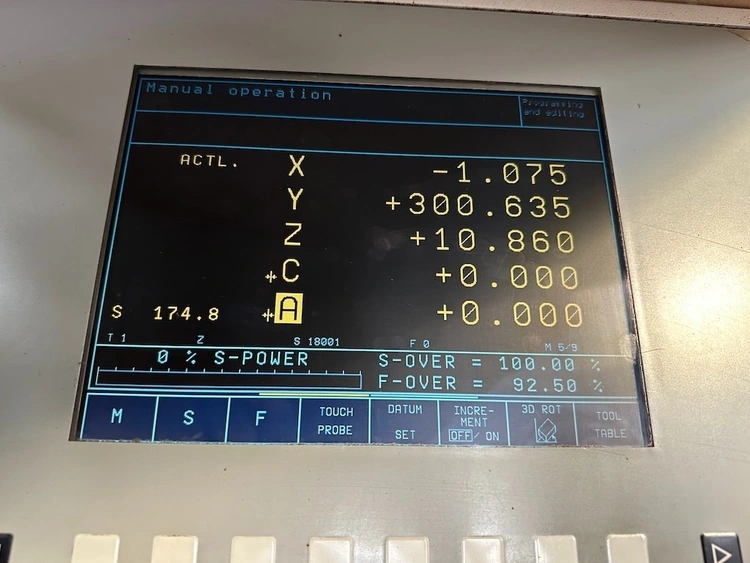

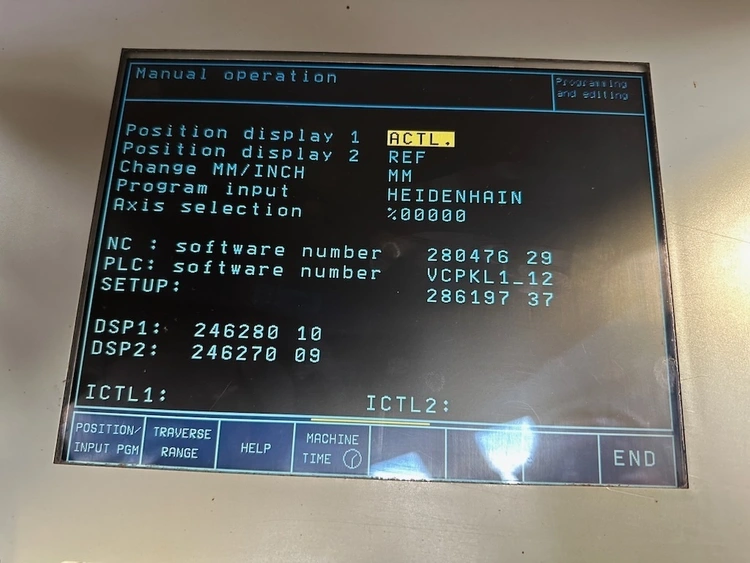

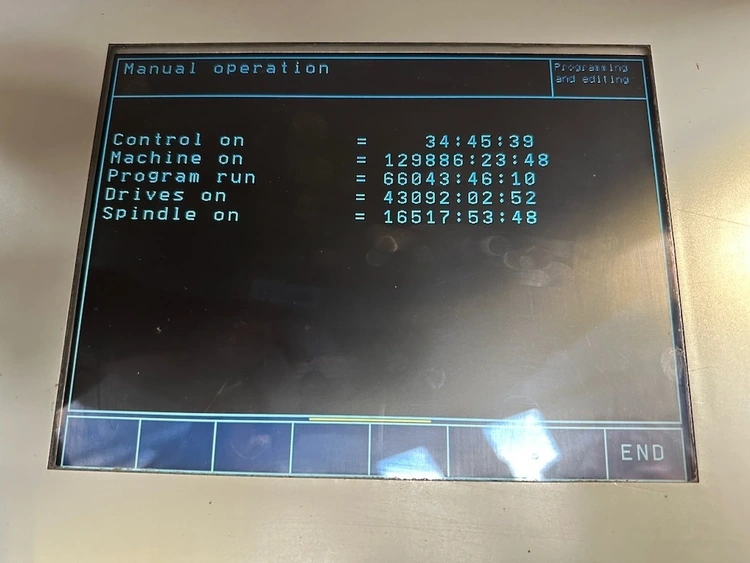

Heidenhain TNC 426/430 M CNC Control System

Serial number: 107.32.99.067

Year of manufacture: 2001

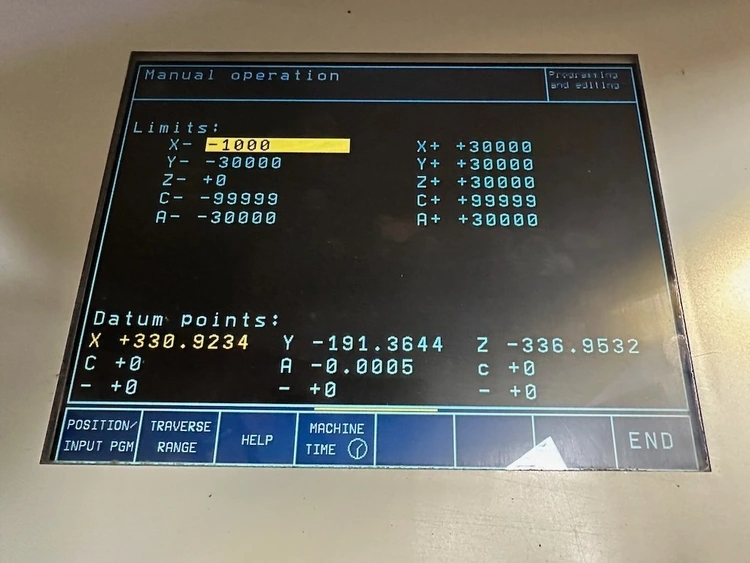

X-axis travel: 530 mm

Y-axis travel: 450 mm

Z axis travel: 450 mm

Rotary tilting table diameter: 400 mm

Maximum table load: 200 kg

Automatic tool changer: TC30: 30 HSK-63A/Din 69893 tools

Maximum rapid traverse: 22 m/min

Spindle speed: 50 - 18,000 rpm

Spindle power:16 kW at 40% 12kW at 100%

Spindle lubrication: Oil-Air

NC rotary tilting table with digitally controlled: 4th and 5th axis

Range of rotation of the table: C-axis: 360 degrees

Maximum rotary speed: 30 rpm

Swivel range: A-axis: -15 to + 122 degrees

Maximum swivel speed: 20 rpm

Machine installation dimensions: Machine weight: 6,500 kg

Width with operator panel and scraping chip conveyor: 2,930 mm

Depth with operator panel: 3,400 mm

Height: 2,645 mm

Equipped with: Step-Tec 18,000 rpm spindle;

Separate spindle cooler;

Unilube oil/air spindle lubrication system;

Coolant tank with scraping chip conveyor;

Separate coolant paper filtration equipment;

Renishaw MP 12 3D IR touch probe; 3D scanning system for tool measurement