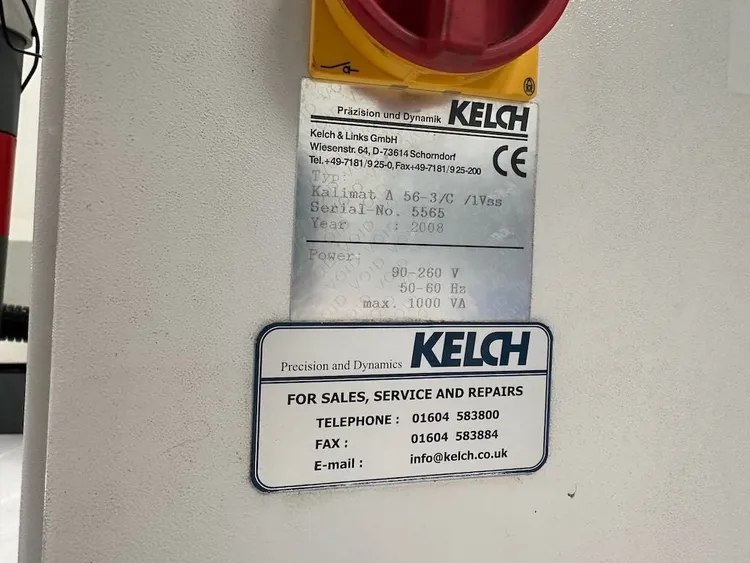

USED KELCH KALIMAT-A

Overview

- Type

- Tool Presetting Machines

- Manufacturer

- KELCH

- Model

- KALIMAT-A

- Stock #

- 40

- Status

- for sale

Description

KELCH KALIMAT-A Tool Presetting Machine for sale. This used equipment offers reliable performance tailored for precise tool measurement needs. Suitable for various industrial applications, ensuring enhanced productivity.

Specifications

| Measuring Range Z | 600mm |

| Measuring Range X | 500mm |

| Dimensions | 2140mm x 660mm x 1950mm " |

Equipped With

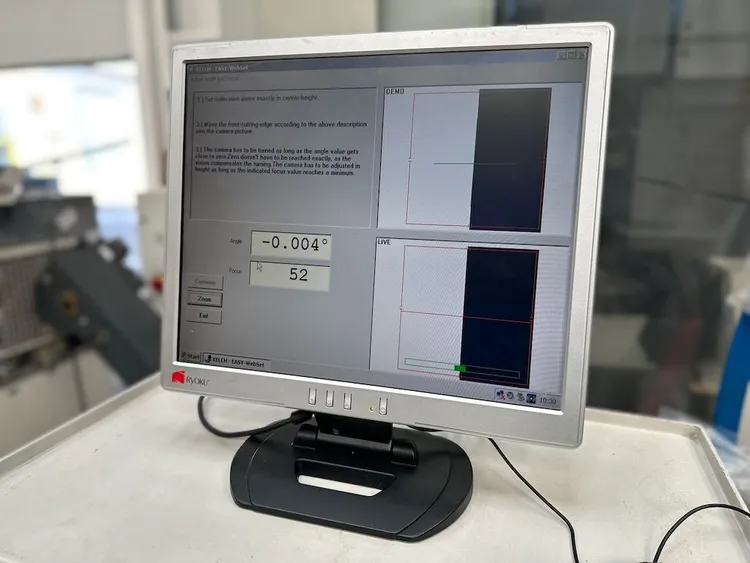

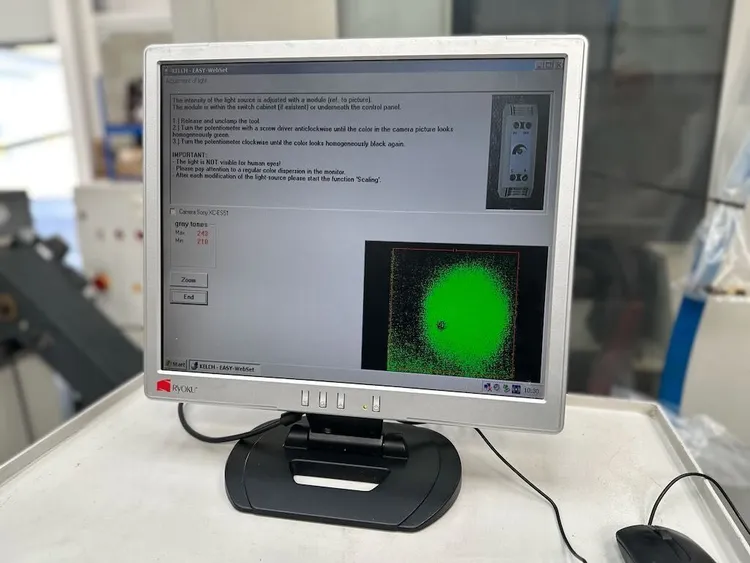

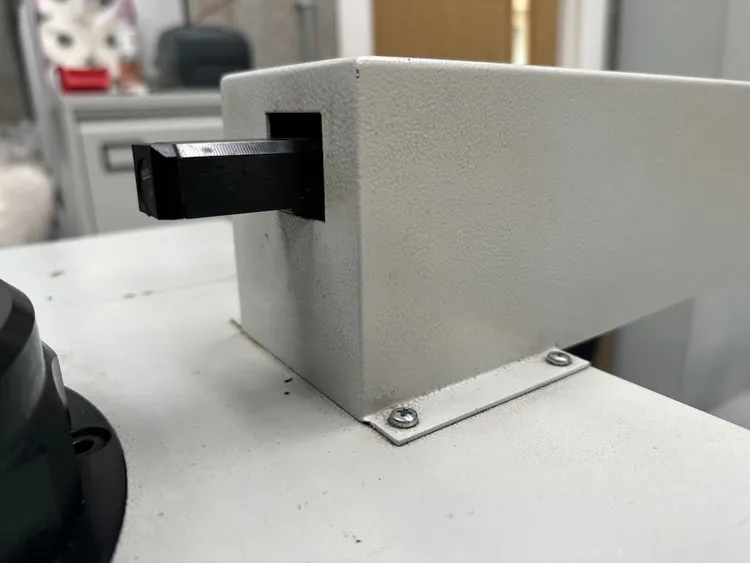

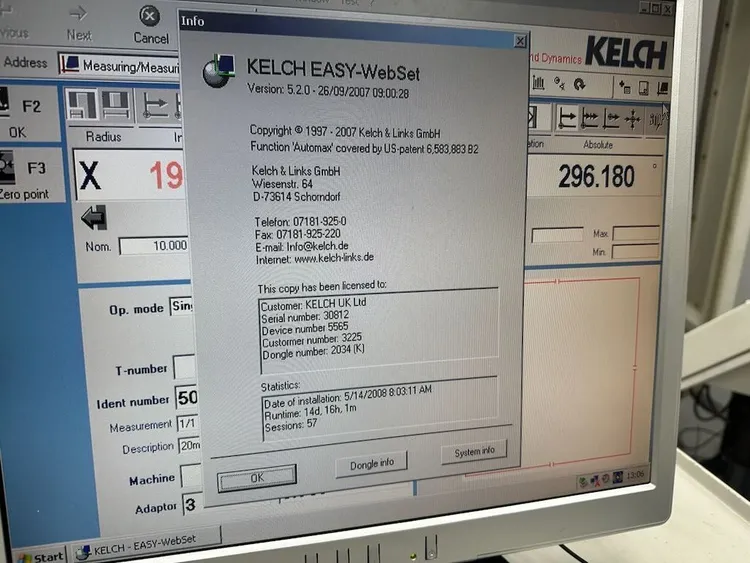

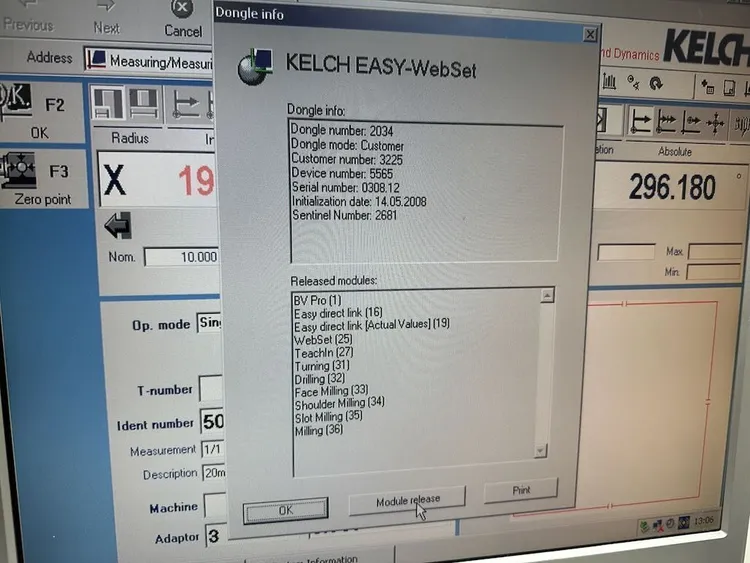

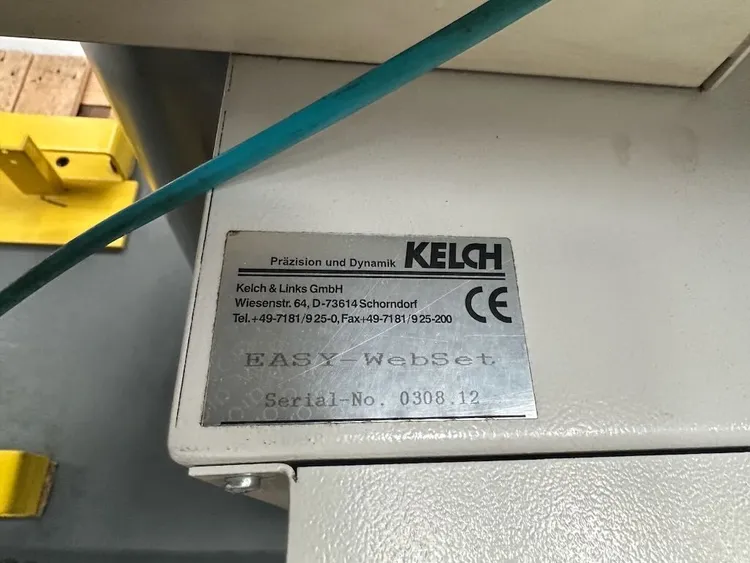

Kelch Kalimat A 56-3/C CNC Tool Presetter High-precision modular tool presetting system fitted with the Kelch MPS (Modular Precision Spindle) for micron-level tool measurement. Can accept all major tool interface types with the correct MPS module. Supplied With: SK50 MPS insert module Additional MPS Modules Available For: SK40 / BT40 SK50 / BT50 HSK32 HSK40 HSK63 HSK100 CAPTO C8 Spindle Performance: MPS spindle accuracy approx. 0.005 micron over 300mm (Kelch spec) Micron-level tool measurement and repeatability Control System: Advantech IPC-610 industrial PC New power supply and hard drive fitted recently Data Output Options: Direct output of measured tool data to CNC machine via DNC link Compatible with Seiki Systems and CIMCO interfaces Can output to FMS / automation cell controller Requires Kelch post-processor for direct CNC offset transfer Removes operator error from tool-data input RFID Tool Data System: Full Balluff RFID read/write system installed Horizontal automatic reader for RFID chips in tool holders Vertical reader/writer for chips in pull studs Compatible with Balluff and some Mazak RFID chips Allows automatic tool identification at the machine tool Key Advantages: Micron-accurate tool presetting Automated offset transfer Reduces scrap and human error Ideal for modern CNC and automated production cells Originally approx. £40,000 new Summary: Premium tool presetting solution with modular MPS spindle system and full RFID tool management capability. Designed for precision machining environments where tool accuracy and automation are essential.